- Joined

- May 7, 2009

- Messages

- 1,666

- Reaction score

- 3

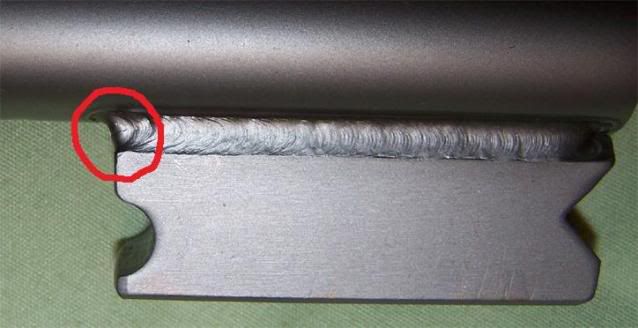

Awhile back I asked the question concerning anyone having trouble with their CVA muzzleloader. I could be the victim of my own post :!: :!: :!: When I finished shooting yesterday I always clean my ACCURA at the range before I leave for home. I noticed 1/8th" cracks (both sides) in the weld between the barrel and the pivit locking piece. ( Sorry I don't know what it's called). I also noticed 2 notches cut in the stock, at the same place where the pivet locking piece goes into the stock. Once it's all put together I ask myself how did this accure because the barrel doesn't touch the metal part of the stock at all. I brought it back to BPS and they said they would send it back to CVA. I'm calling CVA in the morning to see "if this is a natural thing" :!: Reason I say that is I called my friend who hunts with an Optima and after he checked he got back to me with the same news.

:idea: Does anyone else have this problem :?: Check your CVA's gents :!: :!: Mine is only 1 month old and I bet I've only put 150 rounds thru it if that many :!: :!: :!: