- Joined

- Sep 20, 2020

- Messages

- 271

- Reaction score

- 341

HI there

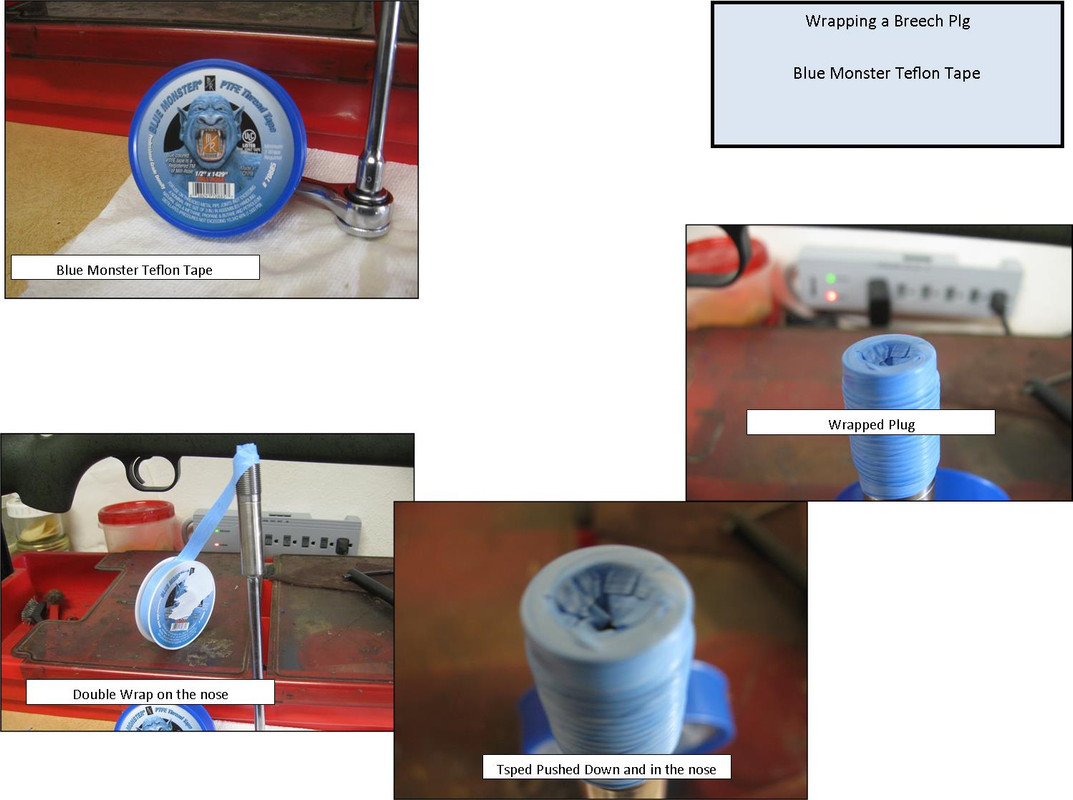

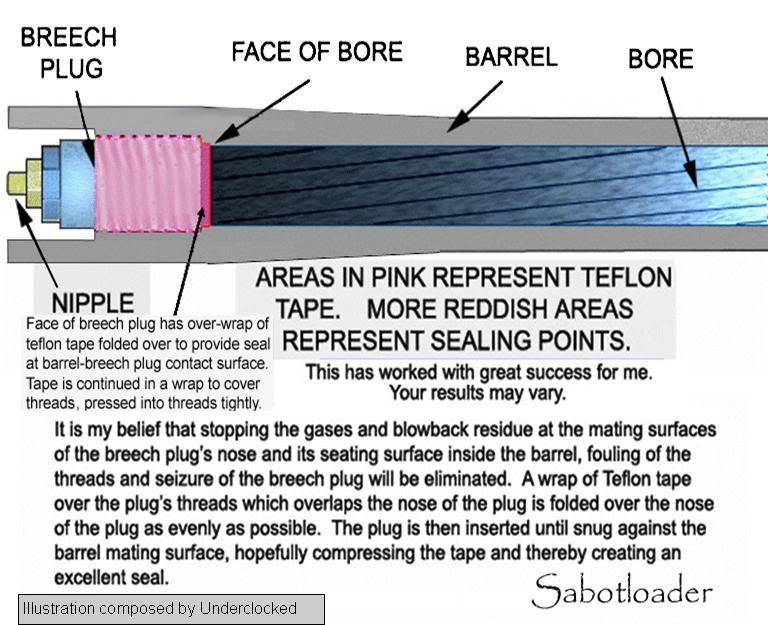

I'm hoping that some one can help me out here. How do you wrap your breach plugs, completely or just the threads. What tape are you using and do the ends of your plugs look the two from my Omega?

I'm at the range yesterday and had a major headache. The Breech plug wasn't in far enough and I couldn't close the breech with a primer in it. The breech plug was in and tight just not in far enough. I ended up backing it out, dumping the powder and starting again. I cleaned the threads in both the gun and on the BP, re-taped like the BP on the right in the photo) One thing that concerned me was that I cleaned out what seemed to be several very small chrome flakes. I checked the bore and where the BP sits and found no issue. I loaded and shot 1 round which has been my practice scoping in the gun to the first shot with a cold and clean barrel. The target above is the 3rd shot in 3 days at 100yds, the actual shot form yesterday is on the left at 9.00 O'clock. I'm a few clicks away from shooting sub MOA on the bull which makes me very happy.

When I got home I stripped the gun down as I always do to clean it. One thing I noticed was fouling on the barrel where the breach plug butts up to the bore. Most of it scraped off relatively easily but in one area that it was so hard that I was concerned that I'd damage the face. I was able to clean it using Ballistol, a bronze brush and an old tooth brush but it took a lot of work. The fouling was difficult to spot and I think has been there for some time. I'm wondering if the sold fouling is responsible for the odd fouling pattern on the ends of the two breech plugs pictured. The plug on the right has never been used by me and came with the gun. What are your thoughts, Is there something that I'm getting wrong here.

One other thing. I'm shooting 777 and seem to be suffering the beginnings of corrosion on the falling block which is blued. I clean the gun after every use and oil it. Is there anything that I can do here? I'm considering changing to Precession Bullets (Cecil Epp's) BP that uses 25ACP brass and small rifle primers as a way of limiting blow back and thinking that I may need to find someone to re-blue the block.

Apologies for the really long post I love shooting my Omega, I'm just so frustrated with my BP issues. Does anyone else have experience with similar issues?

BTW, I think that my flakes of chrome issue may have actually been a scraping from the brass end of my range rod as I pushed the sabot/bullet out before cleaning and reloading at the range.

Thanks in advance for your help.