- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,740

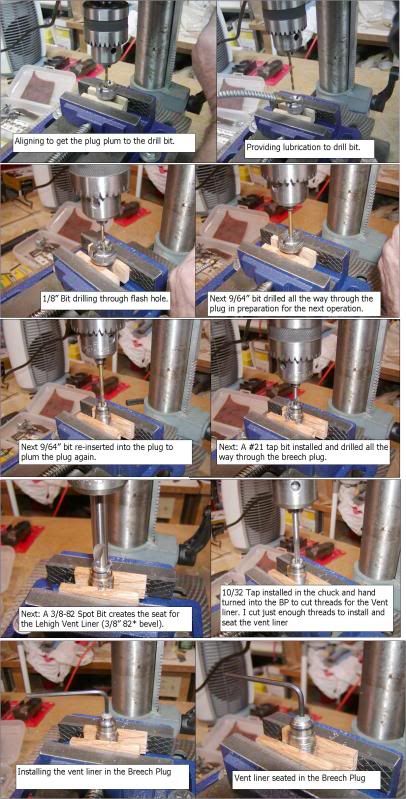

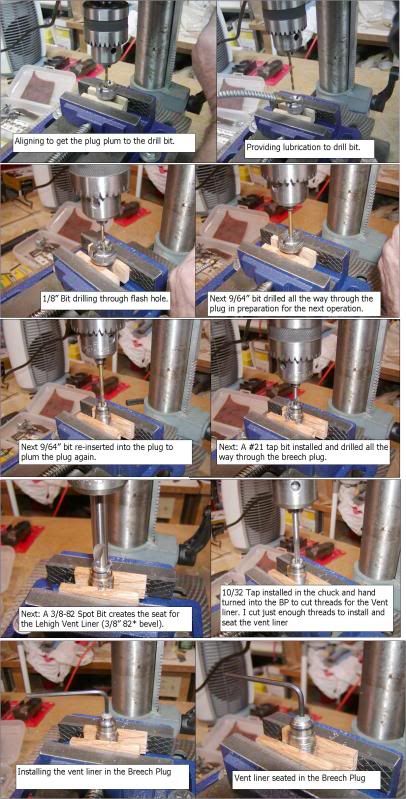

The process started out to simple make a modification in the Triumph breech plug, by opening the flash channel to 0.159? from 0.125? and to exchange the 0.028 flash hole with a Lehigh Vent Liner. Sounds simple, then I decided I should find out more about the gun.

I took all the measurements off the Speed Breech that I thought might be of importance. I also decided I would try to see what the Head Space might be and how all of this came together when the gun was closed.

The Speed Breech may be the longest breech plug on the market, measuring 2.073? inches long + or ? a couple of thousands. This length aids in reducing the blow back pressures felt on the nose of the primer after firing. It also might create a problem in getting heat and pressure to the powder in very cold temperature.

When the Speed Breech is inserted and turned into place and the gun is closed, I thought for sure there would be a gap between the top of the breech and the receiver block. I could close the action with a 0.0015 feeler in between the block and BP but I could not pull it out after the receiver and barrel were closed. It really surprised me how close that tolerance was.

As I looked at the block I also noted the firing pin bushing does stands out approximately 0.014? longer than the block. I measured the primer pocket depth at 0.230?. I inserted some Teflon tape in the bottom of the primer pocket pushed a w209 down onto top of the tape and closed the action. The primer rubbed the pin bushing upon being closed and it did press fit the primer onto the Teflon tape. Opened the gun and pulled the primer and re-measured the primer pocket at 0.224?. That works to be a 0.006? difference. TC got this one very close to being perfect. Because of this measurement there was no sense in worrying about head space.

I also found out that over time the slotted head in the pin bushing on the hammer side can and will work loose allowing the bushing on the breech side to push its way back out and increase the head space. It this has been going on for some time you may now have a hard deposit built up in that area that will not allow the bushing on the block side to protrude as far as it should. Make sure you are cleaning and doing the maintenance on the firing pin.

Finally this morning I did get to the shop to work on the modification of the breech plug. One thing I would like to say is that I am not a machinist ? not even close? There is no doubt in my mind that there is probably a better way to accomplish what it did and the manner that I did it. One thing keeping everything ?plum? in a simple drill press like I have is a challenge (for me at least). There is also no doubt that a machinist with a lathe could and would do a better job.

Here is a pictorial of what I accomplished. The job is complete and the breech plug is installed and ready to go shoot. Should get that done Thursday or Friday.

One last point? the TC Speed Breech is the hardest breech plug I have ever drilled out. I believe it is a quality metal and it probably been through a hardening process. So if other are going to attempt this make sure you have sharp bits, cutting oil to help keep the temperature down and work at it slowly? Keep the temp to a minimum.

I took all the measurements off the Speed Breech that I thought might be of importance. I also decided I would try to see what the Head Space might be and how all of this came together when the gun was closed.

The Speed Breech may be the longest breech plug on the market, measuring 2.073? inches long + or ? a couple of thousands. This length aids in reducing the blow back pressures felt on the nose of the primer after firing. It also might create a problem in getting heat and pressure to the powder in very cold temperature.

When the Speed Breech is inserted and turned into place and the gun is closed, I thought for sure there would be a gap between the top of the breech and the receiver block. I could close the action with a 0.0015 feeler in between the block and BP but I could not pull it out after the receiver and barrel were closed. It really surprised me how close that tolerance was.

As I looked at the block I also noted the firing pin bushing does stands out approximately 0.014? longer than the block. I measured the primer pocket depth at 0.230?. I inserted some Teflon tape in the bottom of the primer pocket pushed a w209 down onto top of the tape and closed the action. The primer rubbed the pin bushing upon being closed and it did press fit the primer onto the Teflon tape. Opened the gun and pulled the primer and re-measured the primer pocket at 0.224?. That works to be a 0.006? difference. TC got this one very close to being perfect. Because of this measurement there was no sense in worrying about head space.

I also found out that over time the slotted head in the pin bushing on the hammer side can and will work loose allowing the bushing on the breech side to push its way back out and increase the head space. It this has been going on for some time you may now have a hard deposit built up in that area that will not allow the bushing on the block side to protrude as far as it should. Make sure you are cleaning and doing the maintenance on the firing pin.

Finally this morning I did get to the shop to work on the modification of the breech plug. One thing I would like to say is that I am not a machinist ? not even close? There is no doubt in my mind that there is probably a better way to accomplish what it did and the manner that I did it. One thing keeping everything ?plum? in a simple drill press like I have is a challenge (for me at least). There is also no doubt that a machinist with a lathe could and would do a better job.

Here is a pictorial of what I accomplished. The job is complete and the breech plug is installed and ready to go shoot. Should get that done Thursday or Friday.

One last point? the TC Speed Breech is the hardest breech plug I have ever drilled out. I believe it is a quality metal and it probably been through a hardening process. So if other are going to attempt this make sure you have sharp bits, cutting oil to help keep the temperature down and work at it slowly? Keep the temp to a minimum.