- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,735

I was finally able to get out to the farm today to do some shooting. It was raining lightly but the time to go was now. Since Dinger Tom cleaned out one of the out buildings I am able to back the pickup in and under and set up under cover.

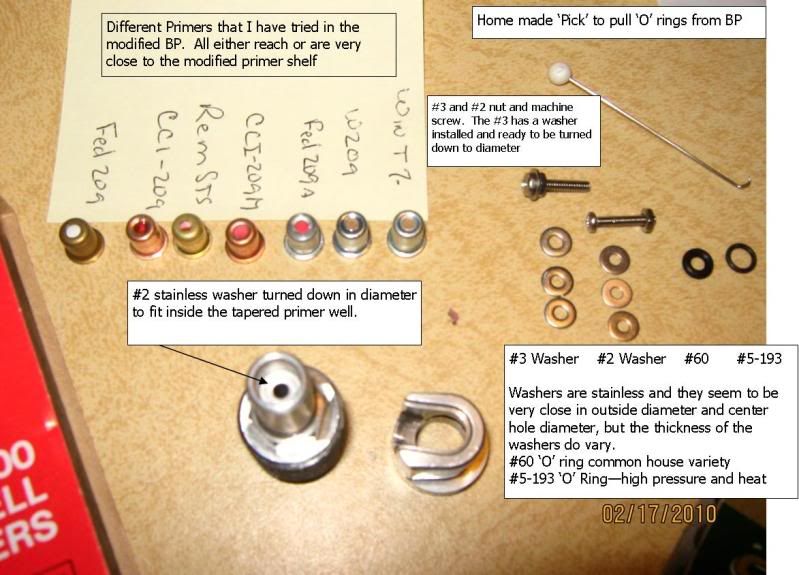

I went our with two objectives... 1. I had finished a NFPJ conversion using a Knight NFPJ domed breech plug. I was really hoping the conversion would reduce the amount of blow back. But, I really have no way of judging the before and after because I have never shot the Knight NFPJ before. But my immediate reaction right now is - dang! not anything to get excited about - Using a FPJ conversion is much cleaner even with used jackets...

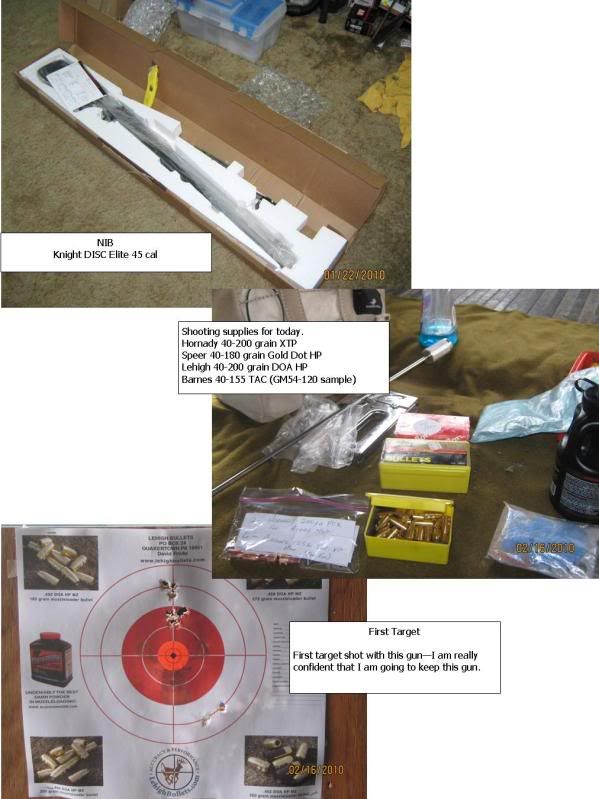

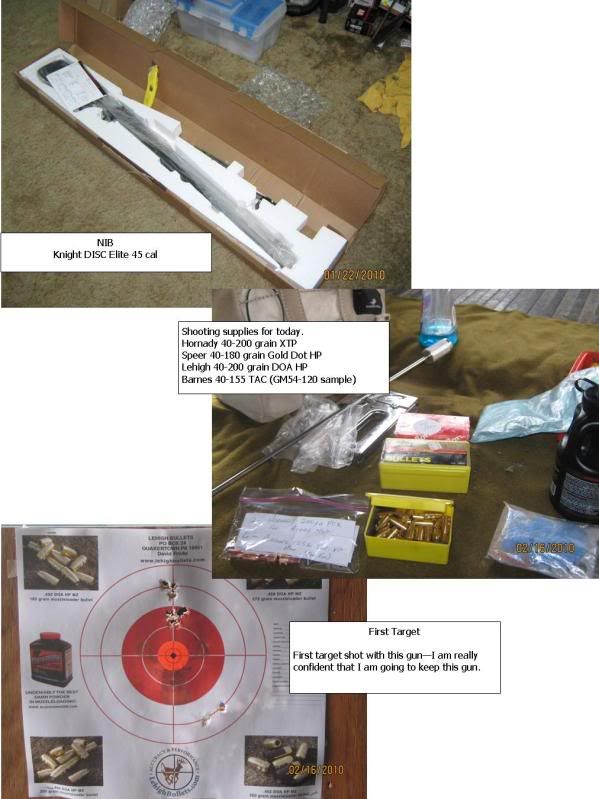

Second objective... shoot this new gun... Grouse had suggested that I just leave it in the box and never shoot it... but man am I glad it did go shoot it. I took it out of the box mounted a Bushnell scope on it with Leupold bases and rings - bore sighted the gun. I also cleaned it - although there was not much to clean - i did not even run any JB's.

One other thing a forum member GM54-120 had sent me some Barnes 40/150 grain TAC's to shoot... He was wondering about velocity and accuracy. From what I saw at 40 yards - accuracy is there. I tried to recover some of them from the clay but was unable to find any of them in the mud + it was raining HARD... so I am going to assume they worked well like all Barnes copper bullets do.

I again, only shot my base load -> 110 grains T7-2f, Winchester T7 primer and stayed with the Harvester smooth blue sabot as they were the first 40 cal sabots that came out of the loading box.

The conversion was not really clean, although using the conversion and the Lehigh primer adapter no fouling or blow back reach rhe scope. The floor of the breech certainly was dirty as was the nose of the bolt - but I have seen it worse. After shot number 10 primers were hard to get out of the primer adaptor - they extracted just fine but fouling in the adaptor area made it difficult for them to slide out just by tipping the gun.

Here is a picture of part of my outing.....

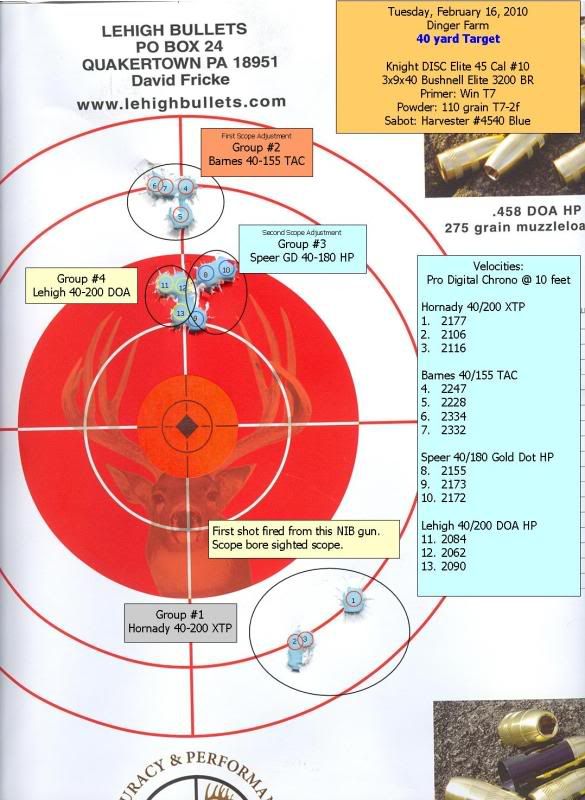

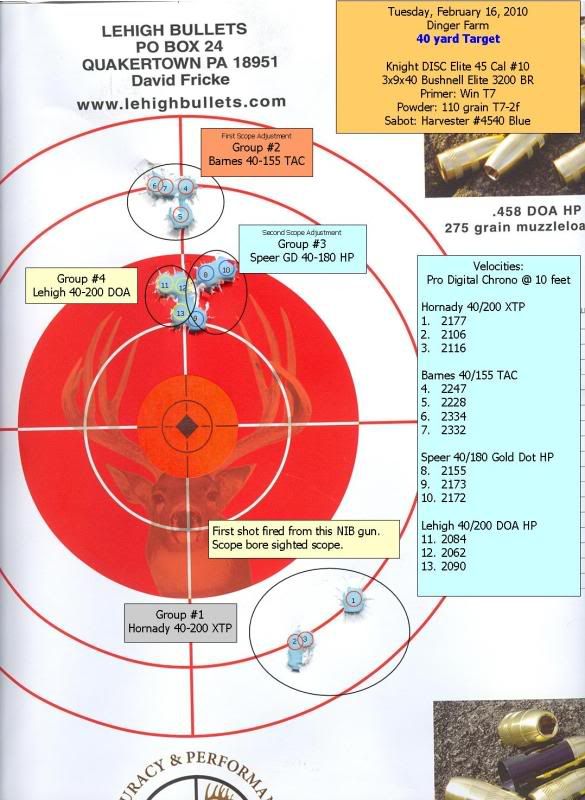

Here are the velocities recorded from todays shooting....

I went our with two objectives... 1. I had finished a NFPJ conversion using a Knight NFPJ domed breech plug. I was really hoping the conversion would reduce the amount of blow back. But, I really have no way of judging the before and after because I have never shot the Knight NFPJ before. But my immediate reaction right now is - dang! not anything to get excited about - Using a FPJ conversion is much cleaner even with used jackets...

Second objective... shoot this new gun... Grouse had suggested that I just leave it in the box and never shoot it... but man am I glad it did go shoot it. I took it out of the box mounted a Bushnell scope on it with Leupold bases and rings - bore sighted the gun. I also cleaned it - although there was not much to clean - i did not even run any JB's.

One other thing a forum member GM54-120 had sent me some Barnes 40/150 grain TAC's to shoot... He was wondering about velocity and accuracy. From what I saw at 40 yards - accuracy is there. I tried to recover some of them from the clay but was unable to find any of them in the mud + it was raining HARD... so I am going to assume they worked well like all Barnes copper bullets do.

I again, only shot my base load -> 110 grains T7-2f, Winchester T7 primer and stayed with the Harvester smooth blue sabot as they were the first 40 cal sabots that came out of the loading box.

The conversion was not really clean, although using the conversion and the Lehigh primer adapter no fouling or blow back reach rhe scope. The floor of the breech certainly was dirty as was the nose of the bolt - but I have seen it worse. After shot number 10 primers were hard to get out of the primer adaptor - they extracted just fine but fouling in the adaptor area made it difficult for them to slide out just by tipping the gun.

Here is a picture of part of my outing.....

Here are the velocities recorded from todays shooting....