big thunder

Member

- Joined

- Apr 6, 2010

- Messages

- 18

- Reaction score

- 0

great site. lots of good info here. i was steered here from a woods and water magizine artical.

i have a t/c hawkin .50, that was a factory assembled rifle i bought new. i'm not sure on the build date somewhere around early 80's. after shooting this rifle for many years, i found a new replacement barrel from green mountain at a very nice price. it's a 1:28 twist stainless barrel. i've shot this barrel for 3 years now and it shoots fairly well.

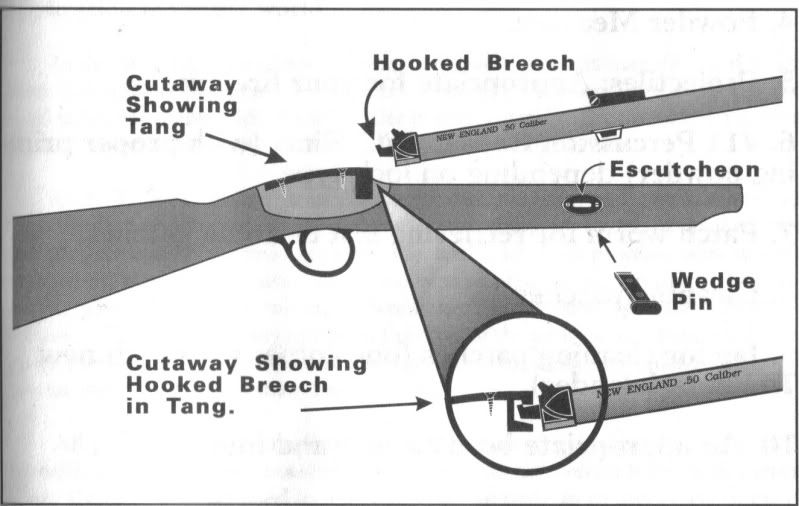

the problem i'm having is the hook on the end of the barrel, which was snug but, never very tight fitting to the receiver flange if thats what it's called? has now loosed up to the point that it has quite abit of movement side to side but, not in or out of the flange. so to say, i can rotate the barrel approximately 1mm. is there any way to tightin this up. theres no apperant peening or mushrooming of either pieces. wondering if a new flange will need to be filed/fitted to the original barrel when replaced? as i'm sure the orignal rb barrel has made it make in wear. that when i dropped this barrel in there wasn't much to wear into looseness.

thanks

i have a t/c hawkin .50, that was a factory assembled rifle i bought new. i'm not sure on the build date somewhere around early 80's. after shooting this rifle for many years, i found a new replacement barrel from green mountain at a very nice price. it's a 1:28 twist stainless barrel. i've shot this barrel for 3 years now and it shoots fairly well.

the problem i'm having is the hook on the end of the barrel, which was snug but, never very tight fitting to the receiver flange if thats what it's called? has now loosed up to the point that it has quite abit of movement side to side but, not in or out of the flange. so to say, i can rotate the barrel approximately 1mm. is there any way to tightin this up. theres no apperant peening or mushrooming of either pieces. wondering if a new flange will need to be filed/fitted to the original barrel when replaced? as i'm sure the orignal rb barrel has made it make in wear. that when i dropped this barrel in there wasn't much to wear into looseness.

thanks