You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What size flash hole?

- Thread starter tpcollins

- Start date

Help Support Modern Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 24, 2009

- Messages

- 15,021

- Reaction score

- 6,882

jsteurrys said:.032"

yep that seems to be the smallest that is VERY dependably. A larger Flash channel size helps too on CVA guns.

Wow - that's small. I found a paper clip, pulled the end burr off with a grinder brushl, and it measured .031"-.0315" but I couldn't get it in my Triumph's plug. I did a half-a$$ attempt with a needle marking it where it stopped and my plug seems to be about .028"-.029" but I'm not exactly sure.

Does this sound about right for the Triumph plug and does anyone drill them out to .032"? A 1/32" drill is .0313, the #67 is exactly .032", a #66 is .033". I want to get a couple bits so I can keep it clean at the range, just wondering which I should get?

I really didn't have any trouble igniting BH209 but I did have the 3rd CCI magnum 209 primer from a new box that failed to fire, even with two attempts. The very next primer in sequence in the tray caused a hang fire. I will try some Federal 209A primers next as I'd hate to have another failure at crunch time with the CCI. Thanks.

Does this sound about right for the Triumph plug and does anyone drill them out to .032"? A 1/32" drill is .0313, the #67 is exactly .032", a #66 is .033". I want to get a couple bits so I can keep it clean at the range, just wondering which I should get?

I really didn't have any trouble igniting BH209 but I did have the 3rd CCI magnum 209 primer from a new box that failed to fire, even with two attempts. The very next primer in sequence in the tray caused a hang fire. I will try some Federal 209A primers next as I'd hate to have another failure at crunch time with the CCI. Thanks.

- Joined

- Mar 31, 2008

- Messages

- 3,500

- Reaction score

- 3

toby bridges says .035 to .036"

tpcollins said:The search feature isn't working well for me at the moment but I assume someone can tell me the recomended minimum diameter (or range)breech plug flash hole diameter for igniting BH209. Thanks.

I guess that depends on whether we are talking about for "best ignition", "blowback control", or a happy medium?

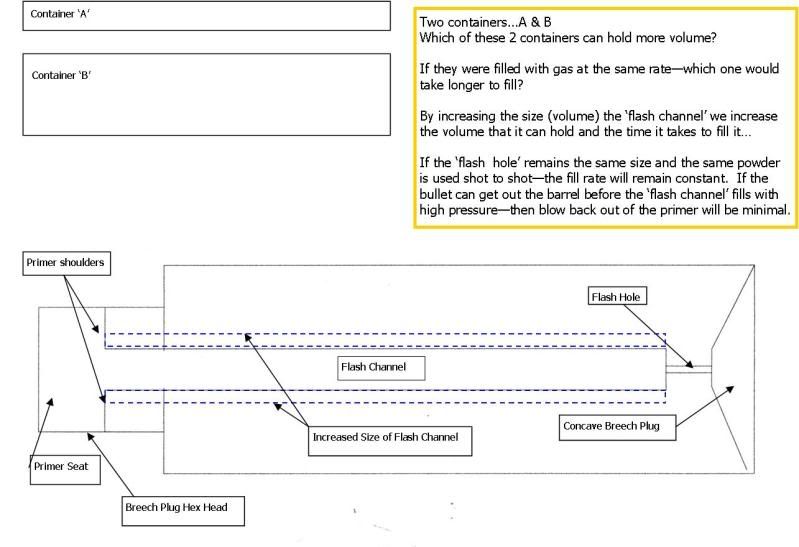

For blowback control, .031 to .032 will get it done as long as you have the right size flame channel to control both primer pressure and load pressure. IMO, the 5/32" is way better than the 1/8" or 3mm flame channels. This size does not load up nearly as fast, and the carbon does not seem to get as hard to remove either.

For best ignition, bigger is better, but the bigger you go, the more pressure on your primer. I have the MU breech plugs that do not utilize a flame channel, but rather a larger diameter flash hole at .042". This plug will ignite Blackhorn 209 with any primer I have tested, 11 in all. This also includes the reduced primers for muzzleloading, and the 209-4 (410) primers.

For standard type breech plugs, I would agree with the others, .032" to .036" should give you a happy medium.

IMO, there is a direct corelation between flame channel diameter and flash hole diameter. The larger diameter flame channel allows the flash hole to be smaller. The smaller diameter flame channel needs a larger diameter flash hole.

This is all just my opinion from nearly two years of shooting Blackhorn 209 through 10 different inlines. Several of these rifles with numerous breech plug designs and modifications.

There is more than one way to skin a cat, and I know what works best for me. The two designs I like best are from two completely different "schools of thought", or "opposite ends of the spectrum" if you will.

The vent liners with a .032 hole work very well and thats what is in the XL BP of both the Triumph and the Endeavor and the regular type plug in my Omega.

But the plug you have is well designed and will work quite well with Blackhorn.

I would use it until it is flame cut an starts blowing back a little then you have to make a choice between a vent liner for 5 dollars or a new plug for 44-48 depending on where you get it.

But the plug you have is well designed and will work quite well with Blackhorn.

I would use it until it is flame cut an starts blowing back a little then you have to make a choice between a vent liner for 5 dollars or a new plug for 44-48 depending on where you get it.

- Joined

- Jul 14, 2009

- Messages

- 401

- Reaction score

- 1

Busta, You are the first person that I've read that has the theory down about the flame channel. I shoot a Rem 700 ML that I modified to use a .32 ACP with a small rifle primer. The breech plug is chambered for the O.D. of the .32ACP case and then to a Lehigh ventliner. The larger volume cuts down on blowback by allowing the primer pressure to expand and then funnel down to the ventliner channel diameter which intensifies the flame similar to the principle that an expansion chamber increases horsepower on a 2 stroke dirt bike engine. I have no problem with BH 209 ignition. I think that increasing the flame channel diameter would solve ignition problems in a lot of breechplug designs.

Busta said:For blowback control said:So if my Triumph's plug currently has roughly a .028" hole with a 1/8" flash channel, then a .032" hole with a 5/32" flash channel would be a balanced ratio as an option? Thanks.

tpcollins said:Busta said:For blowback control said:So if my Triumph's plug currently has roughly a .028" hole with a 1/8" flash channel, then a .032" hole with a 5/32" flash channel would be a balanced ratio as an option? Thanks.

IMO, the 1/8" flame channel with a flash hole less than .031" will not be 100% reliable with Blackhorn 209, UNLESS it is a very long flame channel that will hold more volume. I think your Triumph plug should qualify, and it should be fine as long as you keep the flame channel clear of primer carbon. When carbon builds up in the flame channel it reduces the volume of the chamber. When your flame channel/flash hole combination are too small to hold the primer pressure, the pressure will leak out around or through the primer. You need to maintain heat and pressure on the powder long enough to get reliable ignition. If this heat and pressure is bleeding off around or through your primer, it is not maintaining enough heat and pressure on your powder. When this bleed-off takes place, you will experience misfires and hang fires.

The primer pressure build has to take place either in the Flame channel, or if the flash hole is large enough, in the powder column. Blackhorn 209 has a lot of airspace, with all the little extruded hollow grains. This airspace will need both pressure, and heat for instant ignition. If either the heat or pressure is absent, you will not get reliable results.

There is also another measurement that works in to the equasion, and that is the length of the flash hole. A long narrow flash hole does not allow the volume of heat and pressure to enter the powder column as fast as one that is EITHER shorter and the same diameter, OR the same length and larger diameter. Just figuring out the volume of a cylinder will show this right away.

Now to hopefully answer your question. IMO, the flame channel breech plugs are better served with a 5/32" flame channel, and a .031" to .032" flash hole. The vent liner is not neccessary, but sure makes life easier. You can experiment with flash hole diameters and lengths very easily with a vent liner. The vent liner position in the plug can also determine the length of the flame channel.

I will also stick my neck out and say this. The best breech plug for Blackhorn 209 has not been built yet, at least not by the major manufacturers. Thank God we don't have to wait on them! :wink:

- Joined

- Dec 29, 2007

- Messages

- 4,943

- Reaction score

- 3,087

Busta

You wrote: "I will also stick my neck out and say this. The best breech plug for Blackhorn 209 has not been built yet, at least not by the major manufacturers. Thank God we don't have to wait on them!".

So, in your opinion, what is the 'best' breech plug for BH209??

You wrote: "I will also stick my neck out and say this. The best breech plug for Blackhorn 209 has not been built yet, at least not by the major manufacturers. Thank God we don't have to wait on them!".

So, in your opinion, what is the 'best' breech plug for BH209??

What to do?

I just went thru my wife's assortment of sewing needles and in my Triumph Speed Breech XT, the largest needle that would pass thru the flash hole was one that measured .0255"-.026". And I rotated the needle to get a true measurement from all sides. Then I had a needle that measured .026"-.0265" that would not go all the way thru the flash hole so my plug seams to be a bit small with the 1/8" flash channel.

I want to order some drill bits to use at the range to keep the flash hole cleaned out. Should I get something like a #72 bit (.025") or would you guys have another suggestion? I'll call T/C today to see what their spec is but if mine is on the small side, I'm not sure a replacement plug would gaurantee a larger hole. I have a lathe with a 3-jaw chuck and a tailstock but I'm not sure I could center the XT plug perfectly.

*********************************************************

UPDATE - just got off the phone with T/C.

1st issue with CCI 209M primers - they said there seems to be an issue with Bone Collectors ( didn't say all Triumphs ) that the CCI magnum primers were causing hang/mis-fires and they're recommending using the non-magnum 209 instead. Also, I was to check make sure the screw under the hammer wasn't loose.

2nd issue - they could not tell me what the spec was for the flash hole in the Triumph XT Speed Breech - so I'm still wondering if my .0255"-.026" hole is sufficient?

I just went thru my wife's assortment of sewing needles and in my Triumph Speed Breech XT, the largest needle that would pass thru the flash hole was one that measured .0255"-.026". And I rotated the needle to get a true measurement from all sides. Then I had a needle that measured .026"-.0265" that would not go all the way thru the flash hole so my plug seams to be a bit small with the 1/8" flash channel.

I want to order some drill bits to use at the range to keep the flash hole cleaned out. Should I get something like a #72 bit (.025") or would you guys have another suggestion? I'll call T/C today to see what their spec is but if mine is on the small side, I'm not sure a replacement plug would gaurantee a larger hole. I have a lathe with a 3-jaw chuck and a tailstock but I'm not sure I could center the XT plug perfectly.

*********************************************************

UPDATE - just got off the phone with T/C.

1st issue with CCI 209M primers - they said there seems to be an issue with Bone Collectors ( didn't say all Triumphs ) that the CCI magnum primers were causing hang/mis-fires and they're recommending using the non-magnum 209 instead. Also, I was to check make sure the screw under the hammer wasn't loose.

2nd issue - they could not tell me what the spec was for the flash hole in the Triumph XT Speed Breech - so I'm still wondering if my .0255"-.026" hole is sufficient?

I sent an inquiry to BH209 yesterday and Don @ Western Powders answered with basically the same info here. He said that T/C tried to maintain a .032" flash hole in the Triumph plugs but had heard of instances where some were a bit tight in the .025"-.027" range such as mine.

So I ordered some good ole Made in America drill bits today in several sizes and I'll work my way up to .032". Actually he stated that .035" was the best but I'll take baby steps for now.

So I ordered some good ole Made in America drill bits today in several sizes and I'll work my way up to .032". Actually he stated that .035" was the best but I'll take baby steps for now.

- Joined

- Dec 26, 2009

- Messages

- 1,355

- Reaction score

- 6

Ok all of this talk of flame channel and flash hole has me stupified. I'm gathering that the flame chanel is the distance from the primer to the flash hole which is the hole between the primer and powder? Is this correct?

- Joined

- Dec 29, 2007

- Messages

- 4,943

- Reaction score

- 3,087

Hornet22savage said:Ok all of this talk of flame channel and flash hole has me stupified. I'm gathering that the flame chanel is the distance from the primer to the flash hole which is the hole between the primer and powder? Is this correct?

yes, that is correct, and further, if your rifle is working so far, there is no reason to change any thing.

- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,735

Hornet22savage

Here is a 2 bit drawing I did... hope this might explain it a bit more for you.....

Here is a 2 bit drawing I did... hope this might explain it a bit more for you.....

Sabotloader - I can see how a larger flash channel would create less pressure and reduce blowback. But wouldn't this less pressure also reduce the amount of force pushing the flame thru the flash opening into the powder charge? That would seem to promote a delayed ignition or hangfire.

And unless I'm missing the boat here, seems like this would be similar to using the lower pressure muzzleloader primers.

And unless I'm missing the boat here, seems like this would be similar to using the lower pressure muzzleloader primers.

- Joined

- Dec 24, 2009

- Messages

- 15,021

- Reaction score

- 6,882

tpcollins said:Sabotloader - I can see how a larger flash channel would create less pressure and reduce blowback. But wouldn't this less pressure also reduce the amount of force pushing the flame thru the flash opening into the powder charge? That would seem to promote a delayed ignition or hangfire.

And unless I'm missing the boat here, seems like this would be similar to using the lower pressure muzzleloader primers.

IMO, its possible. That is why you have to find the right balance or/and control blowby through another means such as an o-ring.

Then you even have to figure in the power of the primer. Tonys site has a list of patched round balls fired from a 32cal and just primers. The STS primer is a bit different in that is it "supposed to" not be more powerful just hotter.

Its basically a 3 part equation and your needs. I may want less blowby/residue with mag primers or you might want better ignition for all types of primers in all weather.

My preference is less residue with mag primers and/or better reliability with Win209 and Rem STS primers in bad weather. I can normally get Win209s a bit cheaper and i like the way they fit my CVA plug. They are only 99% though in cold weather.

It may be like using a ML primer but those are $6+ per 100 apposed to as low as $3.20 per 100 for Win209s. If you prefer ML primers then im sure the right balance of channel volume and flash holes size/style is very possible.

But opinions and needs vary.

- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,735

Sabotloader - I can see how a larger flash channel would create less pressure and reduce blowback. But wouldn't this less pressure also reduce the amount of force pushing the flame thru the flash opening into the powder charge? That would seem to promote a delayed ignition or hangfire.

I believe your thought is right on base. You do have to find the right balance of 'Volume Chamber'.... I have been using a a #21 drill bit to open the flaseh channel which is slighly larger than 5/32nds". But this opening in combination with a Lehigh Vent Liner with a flash of .032 works perfect in getting the necessary heat to the powder + reduction of blow back pressure against the primer - of course the shape of the 'vent liner' help in this reduction also.

The other thought I would like to throw out there is... if it were just fire/flame that was being pushed through the 'flash hole' everything would be great.... but the is a whole bunch of other material and debris that are also being forced throught that tiny hole... Only so much can get through at one time...

Using this combination the other day I shot loads of BH and had instant ignition with a Winchester T7 primer, a Winchester W-209 and Fed 209A's.

And unless I'm missing the boat here, seems like this would be similar to using the lower pressure muzzleloader primers.

I do not think you are missing any boat, but pressure is not the whole story.... More important is the heat applied to the powder load. If there is adequate heat and pressure the powder will ignite.

As an example... I shoot a Remington 700ml that has a very tight flash channel and a .030 flash hole. When shooting Fed 209a's or CCI-209M - I get hangfires.... They create so much pressure and debris the flame gets blocked at the flash hole until the pressure drops and the fire can get through. If I shoot that same rifle with a Cheddite 209 or an STS (which have less pressure) - it fires everytime - no hangfires or misfires.

Since I have made a bolt modification to the Remington - I can shoot BH-209 with any of the lower pressure 209 primers.

Thanks sabotloader - at least I'm thinking in the right direction. I found this link about breech plug design and it goes along with what you say.

My Triumph plug has a flash chamber of about 1 3/4'" long which seems like alot. My other concern would be in enlarging the 1/8" flash channel. With a .032" flash hole at the bottom of the .125" chamber, there would be roughly a .0465" step all the way around the flash hole from the 60 degree or so countersink end of the drill bit. I would think a curved funnel shaped entrance into the flash channel would give optimum transfer (probably make it easier to plug up too).

It's probably not available but a 1/8" or 5/32"drill bit with a funnel shaped transition to a .032" tip would be nice. Maybe the Swiss could build one.

http://www.hpmuzzleloading.com/Technical6.html

My Triumph plug has a flash chamber of about 1 3/4'" long which seems like alot. My other concern would be in enlarging the 1/8" flash channel. With a .032" flash hole at the bottom of the .125" chamber, there would be roughly a .0465" step all the way around the flash hole from the 60 degree or so countersink end of the drill bit. I would think a curved funnel shaped entrance into the flash channel would give optimum transfer (probably make it easier to plug up too).

It's probably not available but a 1/8" or 5/32"drill bit with a funnel shaped transition to a .032" tip would be nice. Maybe the Swiss could build one.

http://www.hpmuzzleloading.com/Technical6.html

Similar threads

- Replies

- 19

- Views

- 2K

- Replies

- 0

- Views

- 81

- Replies

- 1

- Views

- 481