- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,735

Headed to the farm this morning to see if my modification to the primer well of the Breech Plug reduced the blow back in the breech area.

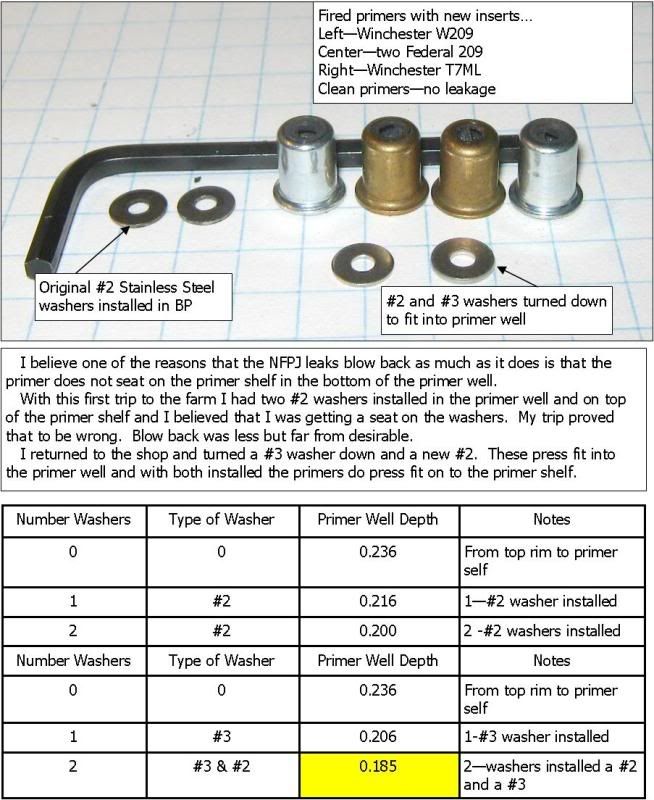

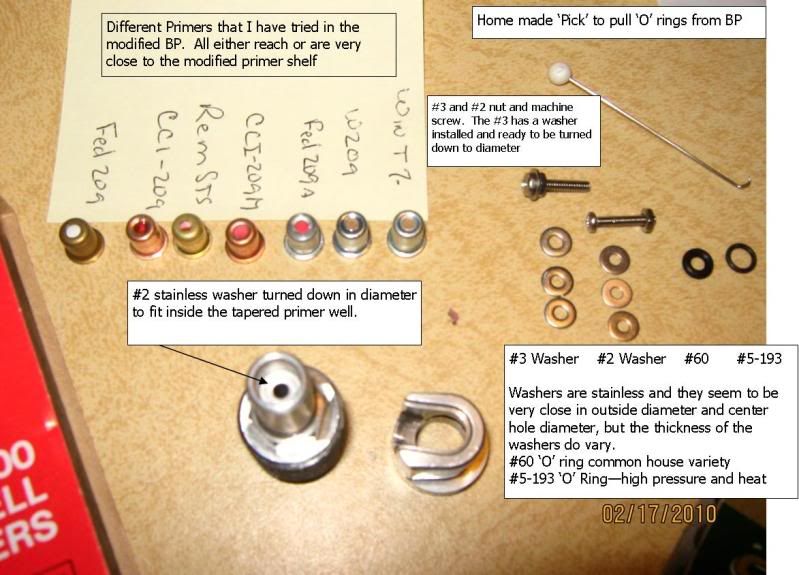

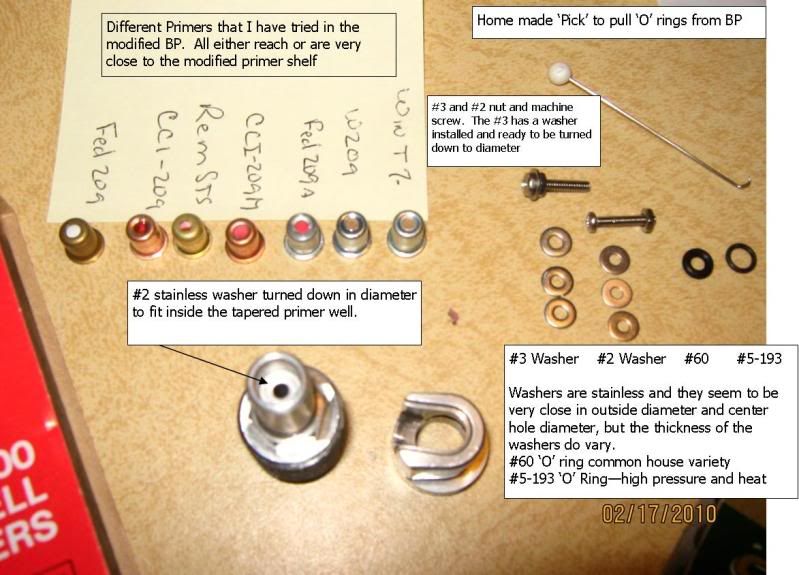

I had installed two #2 Stainless steel washer in the primer well and ontop of the existing primer bench. Several people are using 'O' rings to accomplish the same thing. I am hoping by using the stainless washers I will have a more-or-less permanent application.

Here is a picture showing the first attempt...

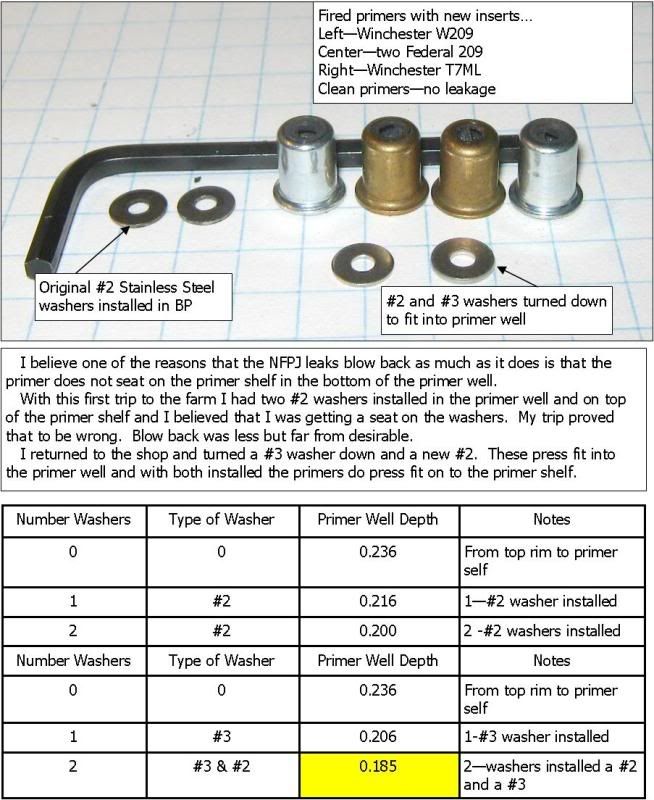

The trip to the farm this morning - proved that a primer well depth of 0.200 is still to deep for the primers to bottom out. The beginning depth is 0.236.

The rifle shot very well with the primer well modification and the Lehigh vent liner in the other end. Just took 6 shots - that was enough to tell be that I had not accomplished my goal. It was some what cleaner but not good enough.

Brought the rifle back to the shop and re-worked the inserts. I now have 2 press fit washers installed in the well. One number #3 and one #2. With this installation the primer well depth was reduced to 0.185. I now can feel the bolt camming action pushing the primer against the primer bench.

I then fired some primers in the shop and I think I have reached the point I was looking for. Hopefully, I will be able to get out tomorrow and shoot the gun again.

I had installed two #2 Stainless steel washer in the primer well and ontop of the existing primer bench. Several people are using 'O' rings to accomplish the same thing. I am hoping by using the stainless washers I will have a more-or-less permanent application.

Here is a picture showing the first attempt...

The trip to the farm this morning - proved that a primer well depth of 0.200 is still to deep for the primers to bottom out. The beginning depth is 0.236.

The rifle shot very well with the primer well modification and the Lehigh vent liner in the other end. Just took 6 shots - that was enough to tell be that I had not accomplished my goal. It was some what cleaner but not good enough.

Brought the rifle back to the shop and re-worked the inserts. I now have 2 press fit washers installed in the well. One number #3 and one #2. With this installation the primer well depth was reduced to 0.185. I now can feel the bolt camming action pushing the primer against the primer bench.

I then fired some primers in the shop and I think I have reached the point I was looking for. Hopefully, I will be able to get out tomorrow and shoot the gun again.