- Joined

- May 19, 2005

- Messages

- 9,205

- Reaction score

- 1,735

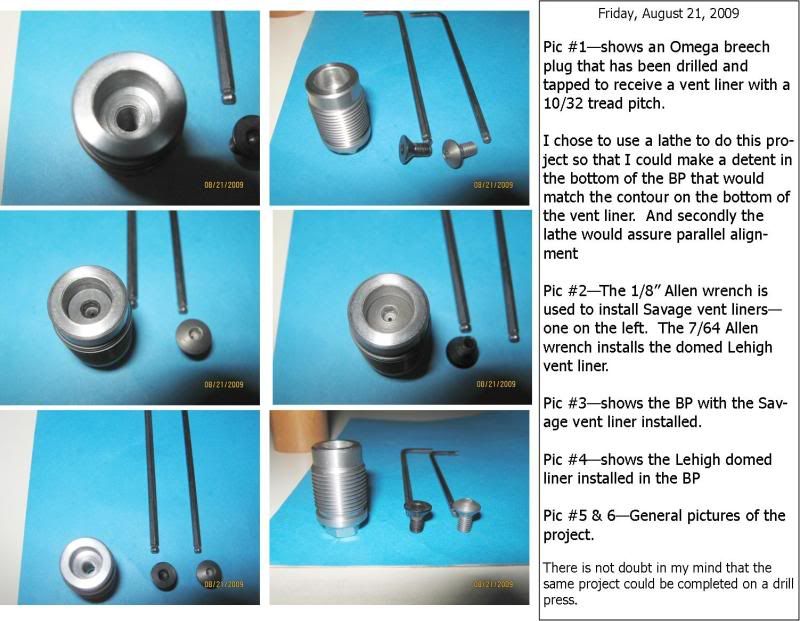

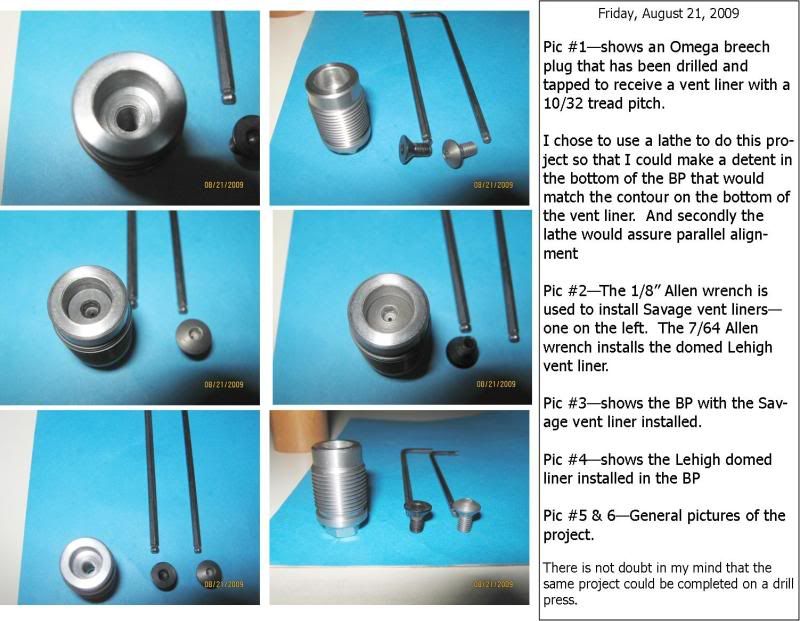

Well since I retired again! and I am suppose to have more time - I tackled my next project... installing a Savage type vent liner in a Breech Plug - preferrably a BP that has been burned out. I got a selection of vent liners from Grouse last week.

Problem... I do not have any burned out BP's like that so I took a brand new Omega BP to a friends Machine Shop - explained to him my problem and my thoughts and he said lets go do it.

I thought he would take it to a drill press and complete the work, but he chose to put it on a lathe as he wanted every thing to be parrallel and he wanted to match the contour of the bottom of the Vent liner with a simular detent in the bottom of the breech plug.

After he took his measurements and got the information he needed he chucked the BP and went to work. It actually took him longer to chuck up the BP than it did to create the VL pocket in the BP, drill out the flash channel, then run a 10/32 tap in the new flash channel. He estimated the next one would take him 15 minutes - start to finish. I am still sure you could do almost as well on a good drill press - think Lee proved that.

The flash hole in the 'Domed' Lehigh liner is .032 and the one in the flat Savage is very very close to the same. I am actually thinking the domed liner might provide less blow back.

Now, if the weather would cool down I would run out to the farm and give it a try. Might be a few days. But I am convinced this is the way to salvage BP's - buying vent liners is a lot cheaper than buying BP's.

If this works as well as I think it might grab a new Knight plug and do the same thing...

Here are some pictures of the project...

Hope this helps explain the project....

Problem... I do not have any burned out BP's like that so I took a brand new Omega BP to a friends Machine Shop - explained to him my problem and my thoughts and he said lets go do it.

I thought he would take it to a drill press and complete the work, but he chose to put it on a lathe as he wanted every thing to be parrallel and he wanted to match the contour of the bottom of the Vent liner with a simular detent in the bottom of the breech plug.

After he took his measurements and got the information he needed he chucked the BP and went to work. It actually took him longer to chuck up the BP than it did to create the VL pocket in the BP, drill out the flash channel, then run a 10/32 tap in the new flash channel. He estimated the next one would take him 15 minutes - start to finish. I am still sure you could do almost as well on a good drill press - think Lee proved that.

The flash hole in the 'Domed' Lehigh liner is .032 and the one in the flat Savage is very very close to the same. I am actually thinking the domed liner might provide less blow back.

Now, if the weather would cool down I would run out to the farm and give it a try. Might be a few days. But I am convinced this is the way to salvage BP's - buying vent liners is a lot cheaper than buying BP's.

If this works as well as I think it might grab a new Knight plug and do the same thing...

Here are some pictures of the project...

Hope this helps explain the project....